Our underlay is manufactured in a complex, three-stage process, consisting of extrusion, cross-linking and expansion. The cross-linked molecular structure results in maximum dimensional stability and resilience with viscoelastic properties.

uncrosslinked

molecular structure

cross-linked

molecular structure

The term viscoelasticity comes from the words viscosity and elasticity. Viscosity results in improved footfall noise while elasticity results in a reduction in impact sound. Two physical and opposing properties are combined in one basic material – the key to our range and the key to its simplicity.

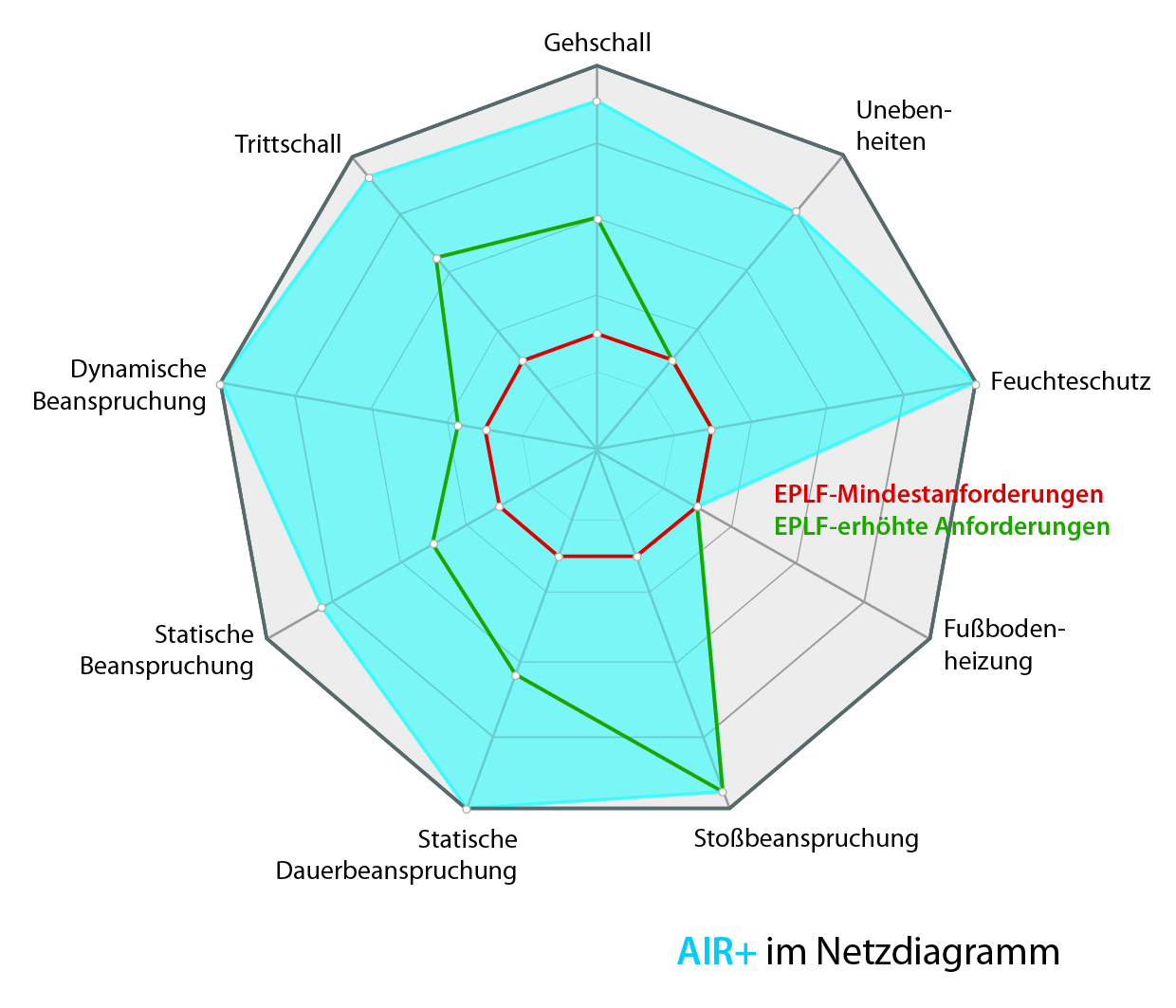

Our foams achieve top ratings in nearly all areas thanks to their viscoelastic properties that are combined with increased dimensional stability. This makes them versatile all-rounders, as

the example of AIR+ illustrates in the radar chart. AIR+ exceeds all of the EPLF’s enhanced requirements. This rating is without equal – a class of it´s own.

AIR+ in the radar chart